"It isn't rocket science," except when it is. On November 8, Aphelion Orbitals, Inc. successfully conducted a demonstration test fire of a flight-scale storable, non-toxic and hypergolic propulsion system for the first time. The test proved the viability of the technology that will power the first and second stages of the company’s Helios nanosatellite launch vehicle. The test occurred at Schuylkill County Airport in eastern Pennsylvania.

"This is a game-changing milestone in the propulsion industry," said Matthew Travis, Aphelion Orbitals Chief Operating Officer after the test. "Never before has a propulsion system of this type been fired at the scale we demonstrated today and we couldn’t be happier with the result."

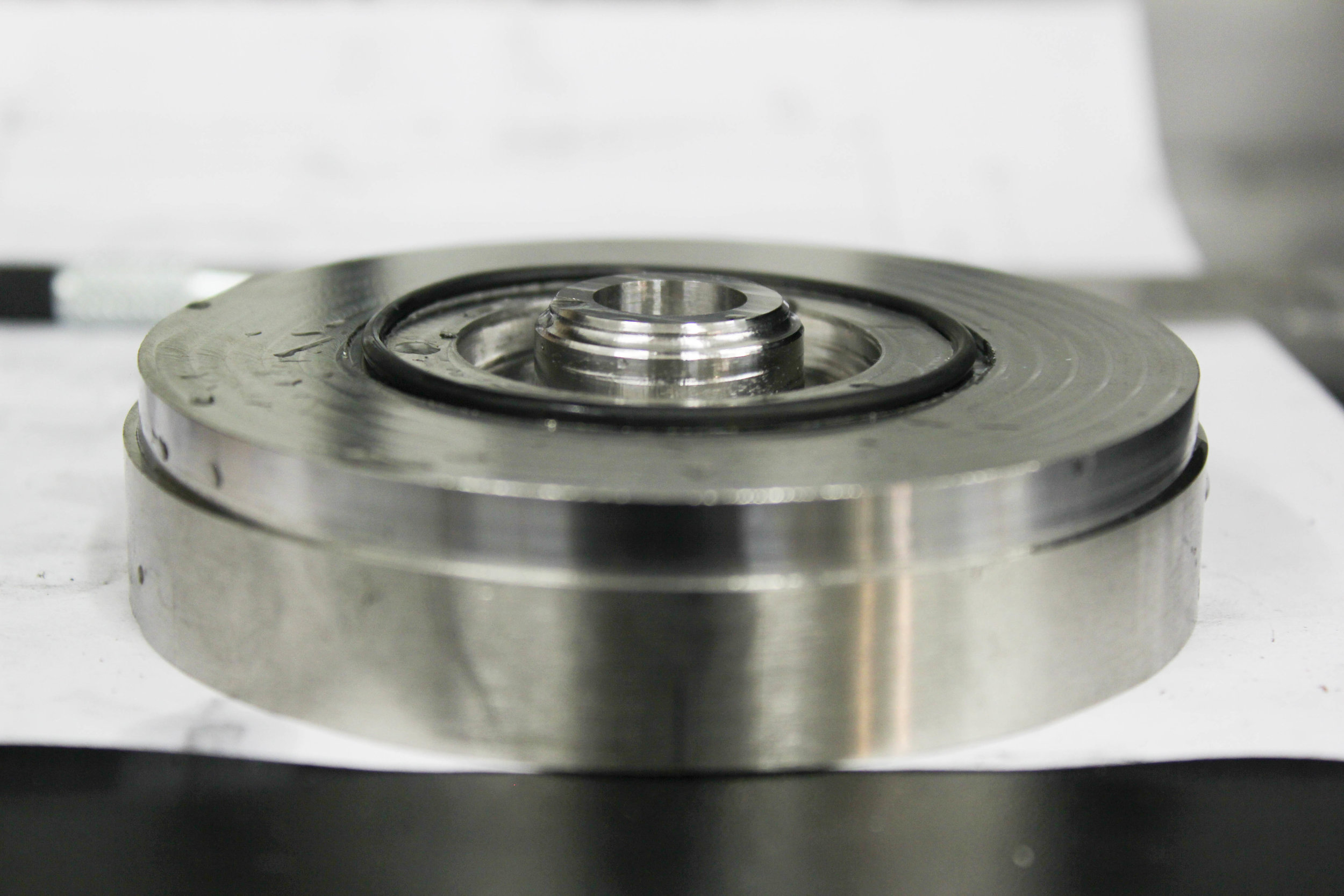

Producing over one ton of thrust for thirty seconds in this latest test, a cluster of 6 identical engines will power the Helios first stage in a clustered aerospike configuration.

Despite loss of the ablative thrust chamber shortly after ignition, the test proceeded as expected for its full duration and utilized the full load of propellant. Notably, the engine ran smoothly with steady combustion for the entire burn, demonstrating the system’s performance and stability even in off-nominal conditions. Just as important, no contingency cleanup of propellants, contaminants or hazardous chemicals was required. Post-test cleanup operations consisted solely of washing down the mobile test stand with water, disconnecting equipment and packing for shipment back to the company’s Union City, NJ facilities. The end result was a real-life, even if unexpected, demonstration of the propellants’ inherent safety and characteristics not seen with other commonly-used hypergols.

Significant research has been conducted over the past 30 years to find a practical non-toxic hypergolic propellant to replace noxious hydrazine and nitrogen tetroxide for in-space as well as Earth-to-orbit launch propulsion. Hypergolic propellants ignite spontaneously on contact and don’t require a separate ignition system. This characteristic makes them reliable and ideal for use on spacecraft in Earth orbit or deep space. They are also potentially desirable for rocket engines powering launch vehicles from the ground to orbit.

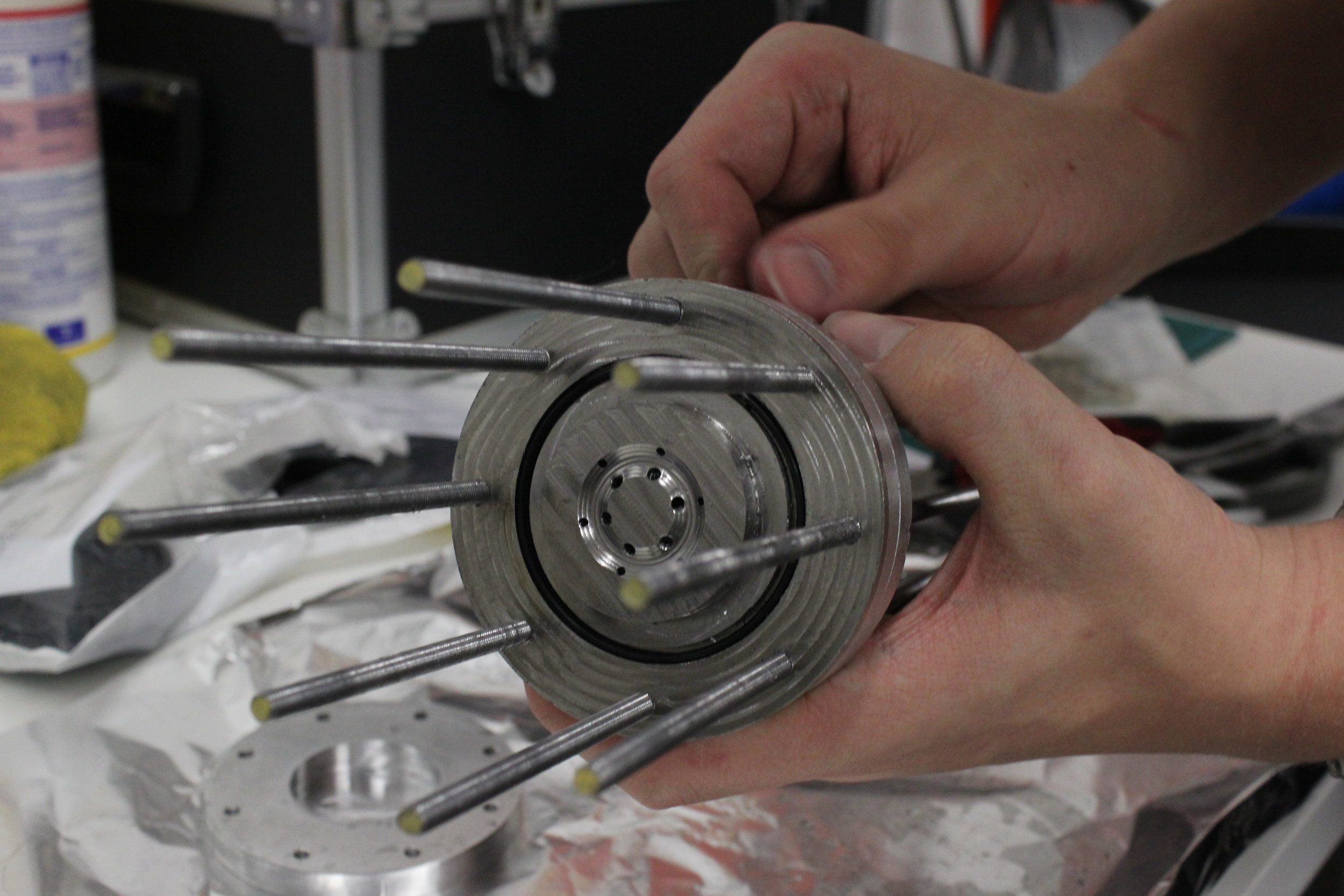

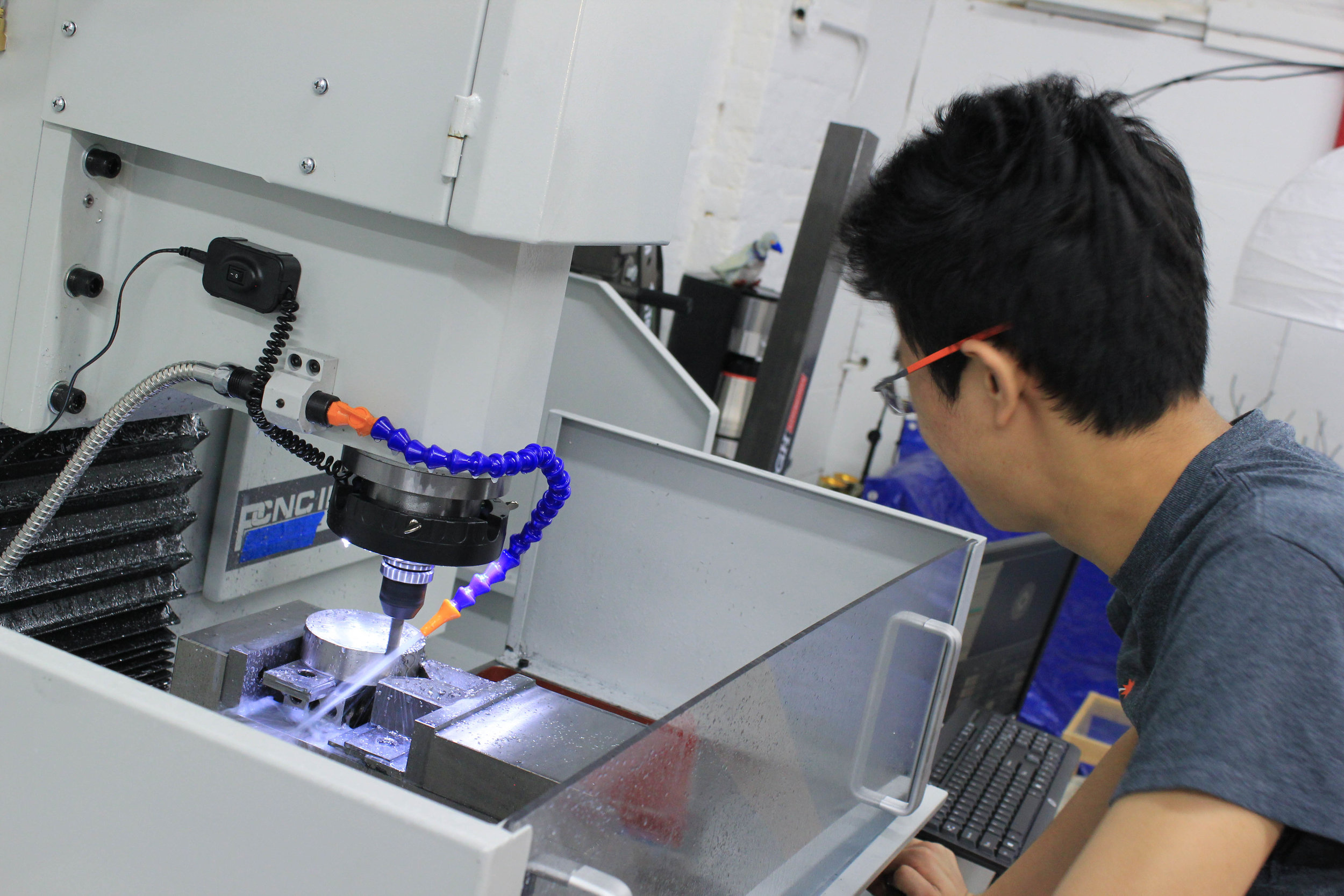

Aphelion Orbitals employees Chris and Peter making final adjustments on our mobile test stand prior to today’s test fire. Credit: Aphelion Orbitals, Inc.

However, because conventional hypergolic propellants are highly toxic and carcinogenic, their use in primary launch propulsion systems has been phased out in the United States over the past decade. This has driven the search for environmentally, non-toxic alternatives to power future launch systems.

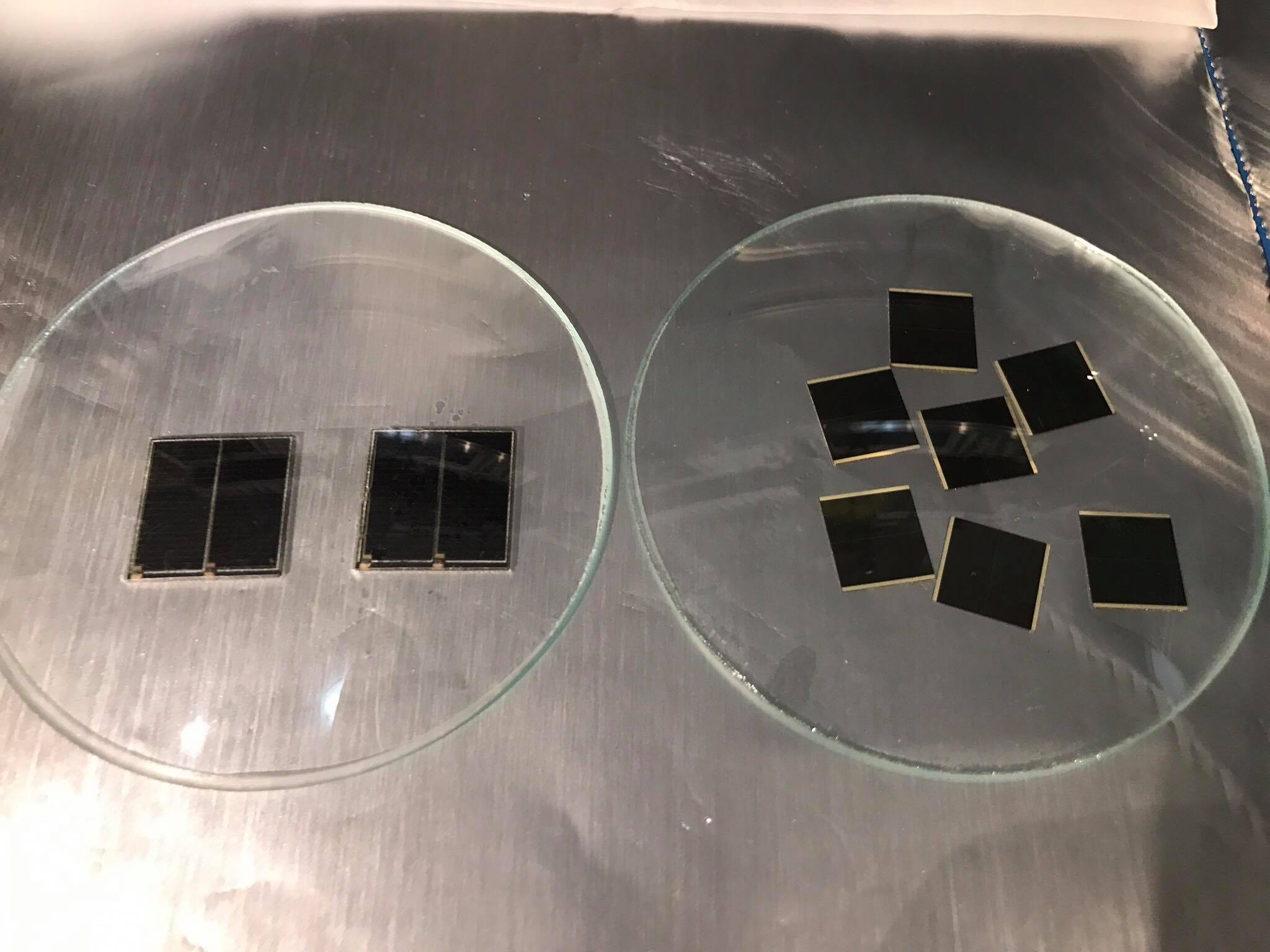

One of the most promising compositions features hydrogen peroxide, ethanolamine and special additives. In addition to being hypergolic and non-toxic, this combination is also environmentally-friendly and fulfills the goals of "green" propellants. Its feasibility has been proven in past lab-scale tests at Sandia National Labs and other organizations.

However, because its performance is generally considered lower than conventional hypergolic propellants, it has never been adopted commercially. Operating at higher pressures and novel mass flow rates, Aphelion Orbitals’ design overcomes this shortcoming and achieves specific impulse (power efficiency) approaching that of the most commonly used rocket propellant, liquid oxygen and RP-1.

Full thrust. Credit: Aphelion Orbitals, Inc.

With the completion of the propulsion system R&D phase, Aphelion Orbitals is poised to move forward with final design and production of the Helios launch vehicle. The company has contracted with Additive Rocket Corporation for production of the first flight engines which will be 3D printed from Inconel rather than using the ablative composite overwrap structure of the development engines.

Aphelion is also participating in the DARPA responsive Launch Challenge competing for a prize up to $12 million to the company that best demonstrates rapid launch and re-launch of nanosatellites from multiple spaceports within two weeks of each other. Both Helios’ inaugural mission and the DARPA Launch Challenge launches are targeted for the second half of 2019.

Shutdown. Credit: Aphelion Orbitals, Inc.